페이지 정보

본문

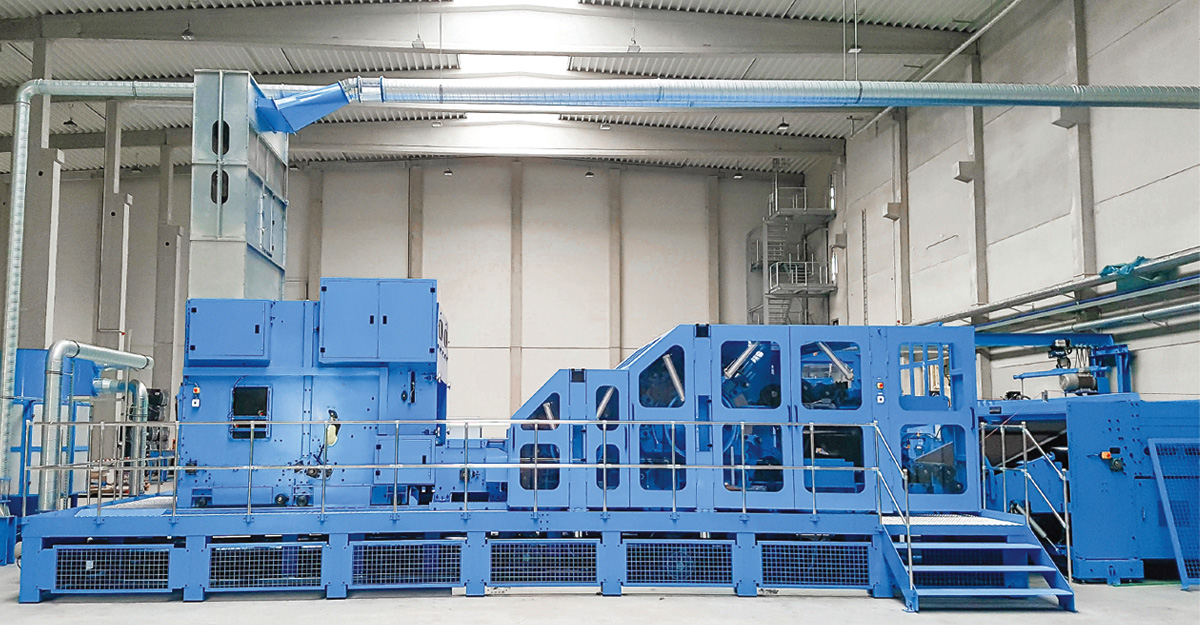

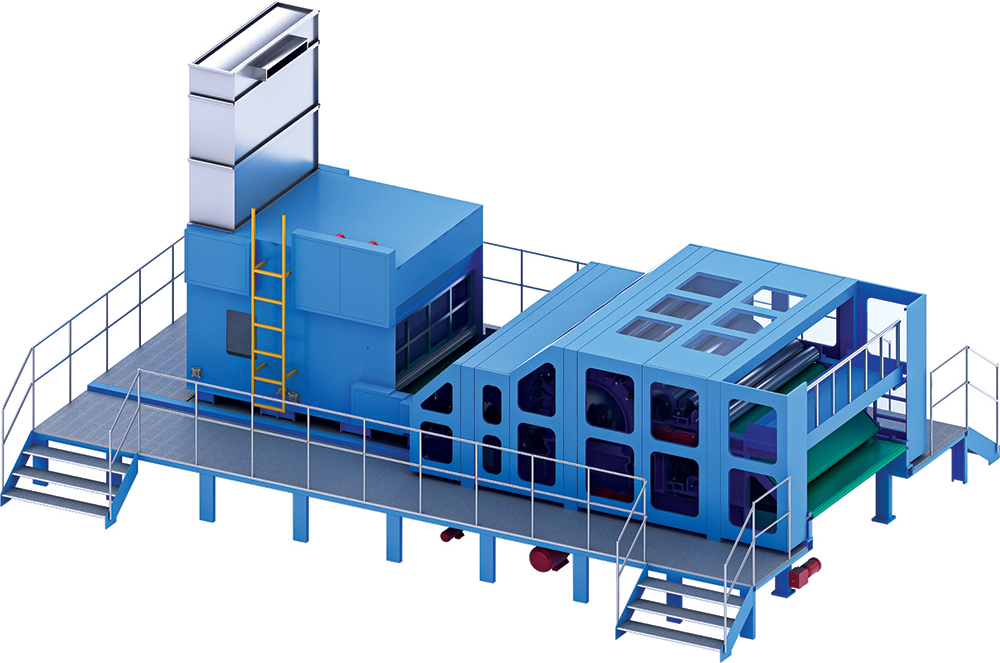

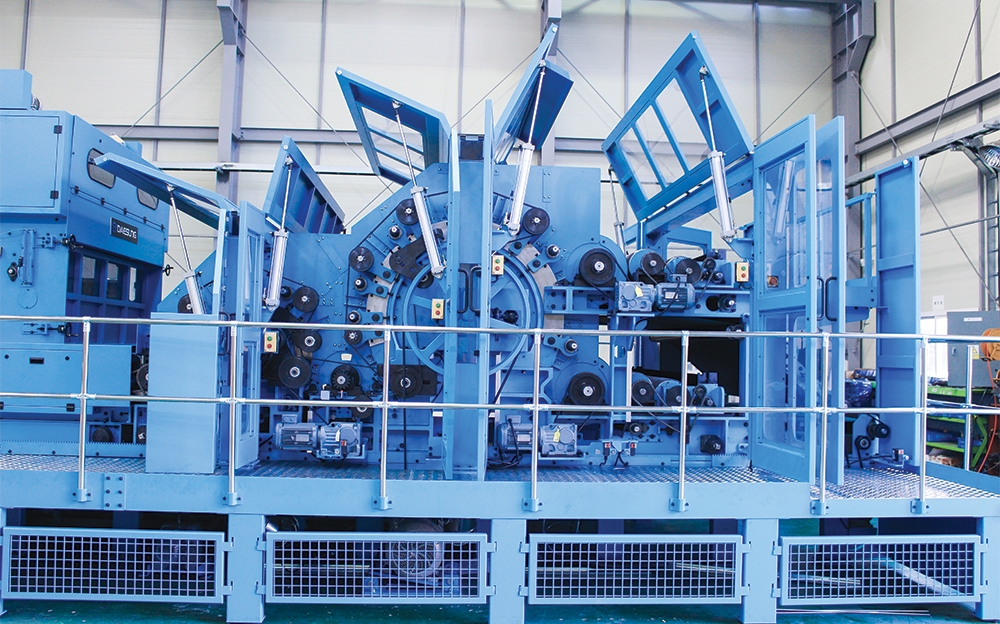

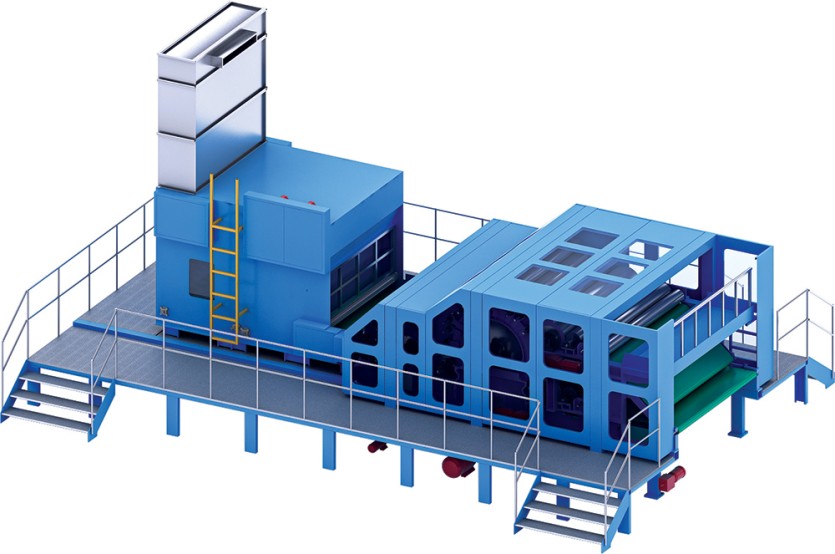

Carding Machine DS-HC120DD

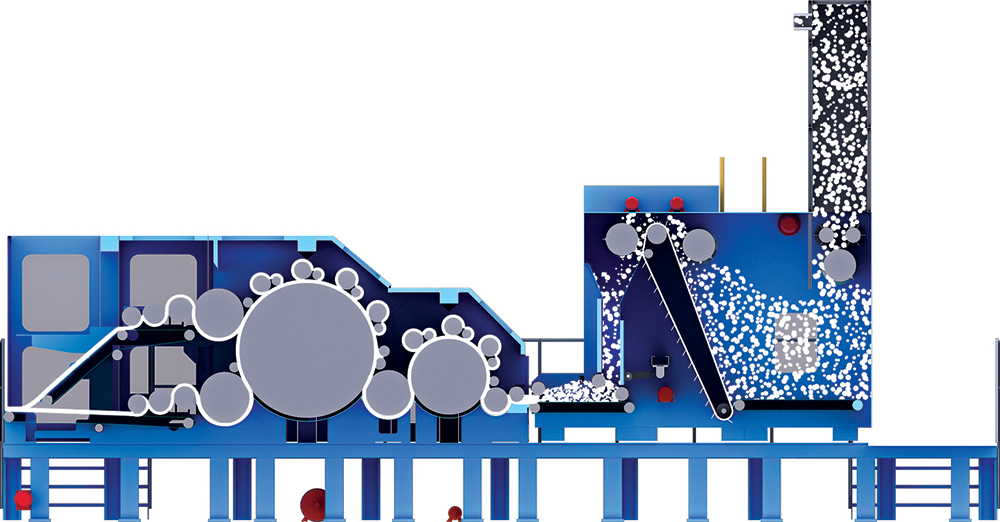

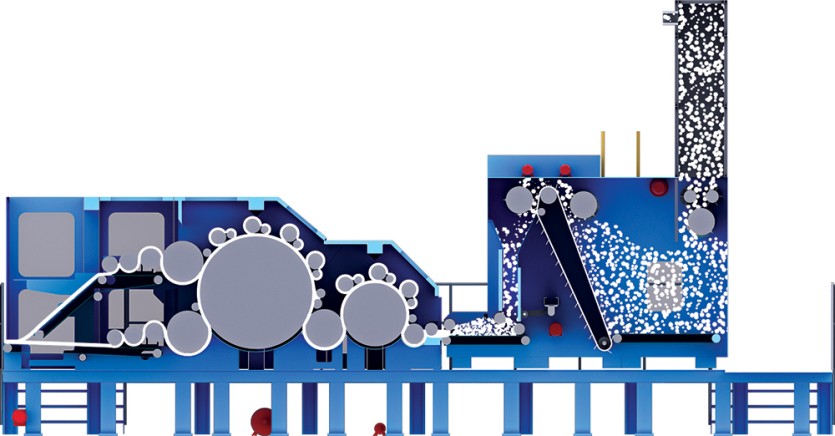

- Opened fiber is carded by turning the roller with a sharp wire wound.

- Different types of rollers have different direction and speed of rotation, and specifications of wound wire are also different.

- Fiber is firstly combed by coarse wire & slow speed roller and is combed by the second with fine wire & fast speed roller, thus the bundled fiber is spread straightly.

- Through a doper and a condenser, an equilibrium or random web is formed and supplied to the next process.

- It is possible to card all types of fiber from low denier to high denier, including synthetic fiber and natural fiber.

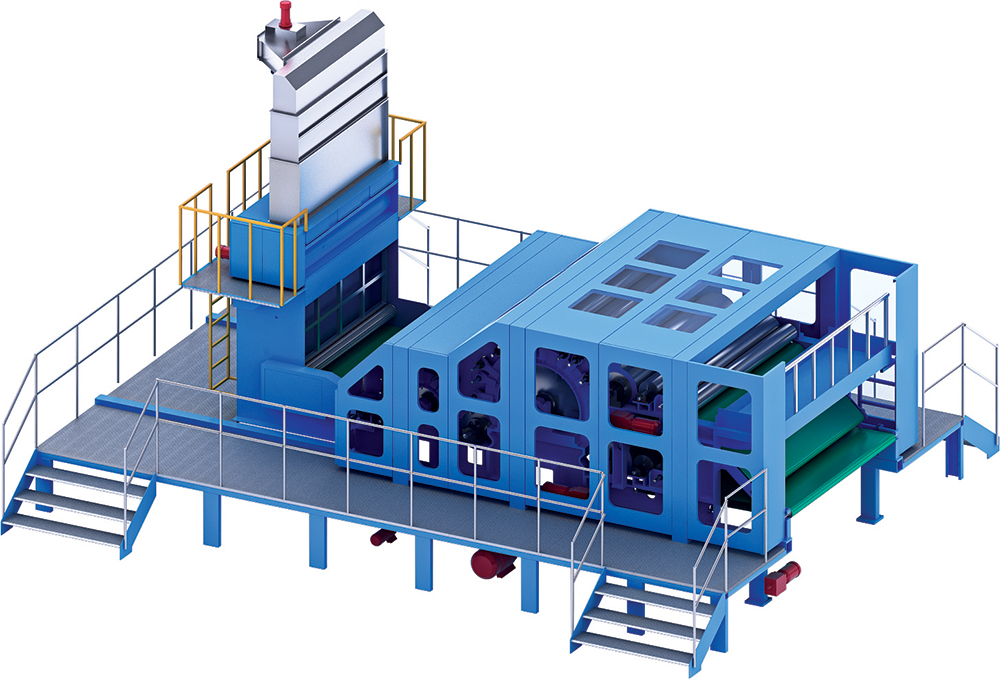

Product Details

- Wire types and specifications are set differently

depending on the fiber and product. - The feed section is configured as either

a 4-roller type(for High-Denier) or

a nose-bar type(for Low-Denier). - The feed is equipped with a metal detection

system that immediately stops production

upon detection of metallic contaminants. - The surface speed of the main cylinder is

up to 1,300 m/min, the web weight ranges

from 15 to 50 g/m², and the production

speed is up to 90 m/min. - Side wool packing and in-side suction

provide optimal carding conditions and

ensure short cleaning times. - The suction system continuously removes

fiber fly and dust from the card,

improving product quality and operator

convenience. - The control system uses inverter drives;

the interlinked program synchronizes

all line drives to prevent web breaks. - Door locks and sensors eliminate hazards

and minimize downtime in emergencies. - EURODRIVE motors provide precise control,

and a touch screen operator panel enables

easy operation.

| Specifications | HC100DD | - | HC120DD |

|---|---|---|---|

| Working Width | 2500mm | - | 3000mm |

| Capacity | 700kg/Hr | - | 1000kg/Hr |

Hopper Feeder Type

Vertical Hopper Type

Hopper Feeder Type

Vertical Hopper Type