DAESUNG MACHINERY CO., LTD.

Specialized Manufacturer of Nonwoven Machinery

"Innovating Today,

Sustaining Tomorrow"

DAESUNG MACHINERY is dedicated to

engineering the most innovative equipment

for nonwoven production lines.

Through continuous R&D and

customer-focused design,

we provide total solutions that

combine convenience,

efficiency,

and advanced performance

across diverse nonwoven industries.

Our systems are engineered not only to

maximize productivity but also to enhance

raw material utilization and

recycling efficiency,

reducing

costs while supporting sustainability.

With proven expertise and customized

solutions, DAESUNG Machinery stands as

your trusted partner, committed

to empowering your success

with

the highest level of technology and service.

-

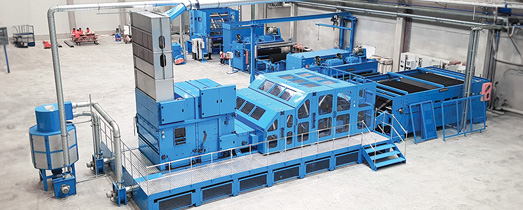

Optimized Turnkey

Nonwoven Production Line

Providing customized total

solutions from design and

manufacturing to installation

and management -

Boosting Productivity

with High-Performance Equipment

Enhancing convenience and

operational stability through

advanced automation systems. -

Maximizing Raw Material Utilization

Minimizing waste and enabling recycling

→ Eco-friendly production with reduced

operating costs -

Professional Installation,

Training, and After-Sales Support

Leveraging global sales experience and know-how to deliver reliable, locally tailored services.